When you walk through a modern refinery or tank farm, the sheer scale of operations seems overwhelming. Towering storage vessels, complex piping networks, and sophisticated processing equipment create an industrial landscape that never sleeps. Yet beneath this impressive infrastructure lies a network of often-overlooked components that keep everything running smoothly and safely.

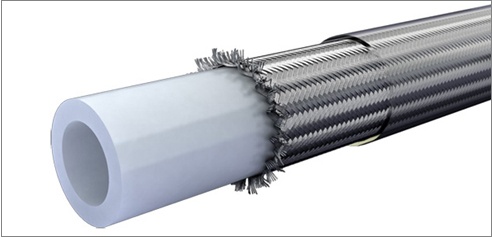

The flexible hose systems threading through these facilities represent far more than simple fluid transfer mechanisms. These engineered solutions handle some of the most demanding applications in industrial operations, from transferring volatile petroleum products to managing high-pressure steam systems. Their ability to adapt to thermal expansion, vibration, and complex routing requirements makes them indispensable in environments where rigid piping simply cannot cope.

Critical Applications in Petroleum Processing

Loading and Unloading Operations: Tank farms rely heavily on specialised transfer systems for moving petroleum products between storage vessels and transport vehicles. These operations demand equipment that can handle varying pressures and temperatures throughout the day. The flexible nature of these systems allows operators to maintain consistent flow rates even when dealing with different product viscosities or ambient temperature changes.

Refineries process millions of litres of crude oil and refined products daily, creating logistics challenges that require adaptable solutions. Traditional rigid piping systems struggle with the dynamic nature of loading bays, where truck positions vary and equipment must accommodate different vehicle configurations. The flexibility becomes particularly crucial during winter months when thermal contraction affects equipment positioning.

Steam Distribution Networks: High-pressure steam systems present unique challenges in refinery operations, requiring transfer solutions that can handle extreme temperatures and pressures. Steam applications often involve rapid temperature changes that would stress rigid connections beyond their design limits. The thermal expansion characteristics of flexible systems allow them to absorb these stresses naturally.

Process steam requirements vary significantly throughout refinery operations, from low-pressure heating applications to high-pressure turbine feeds. Each application demands specific pressure ratings and temperature capabilities, making system selection critical for operational safety and efficiency.

Safety Considerations in Hazardous Environments

Chemical Compatibility Requirements: Petroleum facilities handle diverse chemical products that can be highly corrosive or reactive with standard materials. Compatibility between transfer systems and process fluids becomes a primary safety concern, as material failure could result in dangerous leaks or environmental contamination. Proper material selection prevents chemical degradation that might compromise system integrity over time.

Different petroleum products present varying compatibility challenges, from light hydrocarbons that can permeate certain elastomers to heavy crude oils that require specific temperature maintenance. Understanding these interactions helps facility managers select appropriate systems for each application.

Fire Safety and Emergency Response: Refinery environments carry inherent fire risks that influence equipment selection and installation practices. Transfer systems must maintain integrity during emergency situations, including exposure to radiant heat from nearby fires. Emergency disconnect capabilities become essential features that allow rapid isolation of fluid transfer operations.

The design of emergency response procedures often depends on the quick-disconnect capabilities of flexible transfer systems. These features enable rapid shut-off and system isolation, potentially preventing minor incidents from escalating into major emergencies.

Maintenance and Operational Efficiency

Inspection and Replacement Protocols: Regular inspection programmes help identify potential issues before they lead to costly failures or safety incidents. Visual inspections can reveal surface wear, chemical attack, or mechanical damage that might compromise system performance. Establishing clear inspection schedules based on operating conditions helps maintain system reliability.

Replacement planning becomes particularly important in continuous operation facilities where unscheduled downtime carries significant costs. Predictive maintenance approaches using inspection data allow facilities to schedule replacements during planned maintenance windows rather than responding to emergency failures.

Cost-Effective Maintenance Strategies: Flexible systems often provide maintenance advantages over rigid alternatives, particularly in applications involving frequent connection and disconnection cycles. The ability to replace individual components without major system modifications reduces both material costs and labour requirements. This modularity proves especially valuable during plant expansions or process modifications.

Key maintenance considerations include:

- Regular pressure testing to verify system integrity

- Chemical compatibility verification for new product introductions

- Temperature monitoring during extreme operating conditions

- Documentation of inspection findings and replacement history

- Training programmes for proper handling and installation procedures

Performance Optimisation: Understanding the relationship between system design and operational efficiency helps facilities maximise their investment in transfer equipment. Proper sizing ensures adequate flow rates without excessive pressure drops that waste energy. Temperature management prevents product degradation and maintains optimal viscosity for efficient transfer operations.

Conclusion

The sophisticated infrastructure of modern refineries and tank farms depends on reliable, flexible transfer solutions that adapt to demanding operational requirements. These systems provide the backbone for safe, efficient fluid handling operations that keep critical energy facilities running smoothly. Investing in quality transfer systems and maintaining them properly protects both operational efficiency and worker safety. Consider evaluating your current fluid transfer systems to ensure they meet the evolving demands of your facility’s operations.